Clutch pressure plates, though seemingly inconspicuous, play an integral role in your vehicle’s performance. As a key component of your car’s clutch system, they ensure the smooth and efficient transfer of power from the engine to the transmission. This comprehensive article will delve into the inner workings of clutch pressure plates, explore different types, and discuss how upgrading this essential part can elevate your driving experience.

The Clutch System: A Closer Look

Clutch System Components

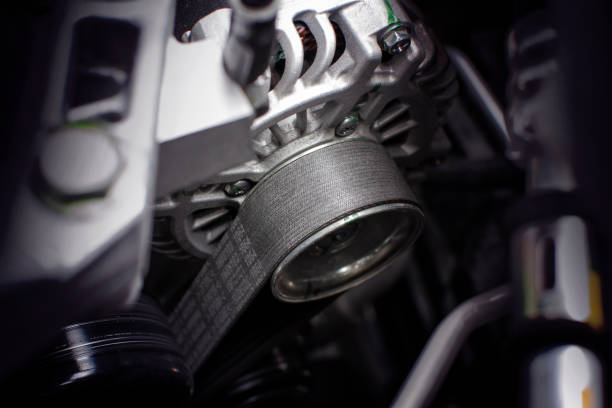

The clutch system is a crucial part of any manual transmission vehicle. Serving as a link between the engine and transmission, it enables the driver to control the flow of power. This system comprises several components, including the flywheel, clutch disc, pressure plate, release bearing, and clutch fork. The pressure plate, in particular, is responsible for holding the clutch disc against the flywheel, facilitating torque transmission.

The Crucial Role of Clutch Pressure Plates

Clutch pressure plates are spring-loaded mechanisms that engage and disengage the clutch disc. When you press the clutch pedal, the pressure plate releases the clutch disc from the flywheel, disconnecting the engine from the transmission. This action allows you to change gears or stop the vehicle without stalling the engine. Conversely, when you release the clutch pedal, the pressure plate pushes the clutch disc against the flywheel, reconnecting the engine and transmission.

A Guide to Different Types of Clutch Pressure Plates

Diaphragm-Type Pressure Plates

Diaphragm-type pressure plates are the most common in modern vehicles. They employ a single, conical diaphragm spring that provides even pressure across the clutch disc. This design results in a lighter pedal feel, making it easier for drivers to operate the clutch. Diaphragm-type pressure plates are suitable for everyday driving and light-duty performance applications.

Coil Spring-Type Pressure Plates

Coil spring-type pressure plates use multiple coil springs arranged around the circumference of the plate. These springs apply pressure on the clutch disc and provide a more progressive, firmer pedal feel. Coil spring-type pressure plates are suitable for high-performance and heavy-duty applications, such as racing and towing. However, they may require more pedal effort and may not be ideal for daily driving.

Multi-Plate Clutches

Multi-plate clutches feature multiple clutch discs and pressure plates, providing increased torque capacity. These systems are commonly used in high-performance and racing applications. While they offer improved performance, multi-plate clutches can be more challenging to operate, making them less suitable for everyday driving.

Upgrading Your Clutch Pressure Plate: Assessing Your Needs and Choosing the Right Type

Evaluating Your Driving Habits and Requirements

Before upgrading your clutch pressure plate, it’s essential to evaluate your driving habits and requirements. Consider factors such as your vehicle’s power output, intended use (daily driving, racing, towing), and desired pedal feel. These factors will help you determine the most suitable pressure plate for your needs.

High-Performance Pressure Plates

High-performance pressure plates are designed to handle increased power levels and provide more aggressive clutch engagement. They often feature stronger materials, enhanced heat resistance, and a higher clamping force to handle the demands of spirited driving, track use, or heavy-duty applications. Keep in mind that upgrading to a high-performance pressure plate may result in a firmer pedal feel and faster clutch wear.

Lightweight Pressure Plates

Lightweight pressure plates feature reduced mass compared to stock pressure plates. This reduction in weight can lead to quicker engine response and improved acceleration, particularly in high-revving applications. However, lightweight pressure plates may not provide the same level of durability as their heavier counterparts, making them better suited for racing or performance-oriented applications rather than daily driving.

Choosing the Right Material

The material used for the pressure plate can impact its performance and longevity. Common materials include cast iron, nodular iron, and aluminum. Cast iron is often found in stock pressure plates and provides excellent durability and heat resistance but can be heavy. Nodular iron is an upgrade from cast iron, offering increased strength and a lighter weight. Aluminum pressure plates are the lightest option but may not be as durable as iron-based materials, making them better suited for racing and high-performance applications.

Installation and Maintenance: Ensuring Optimal Performance

Professional Installation

While it is possible to install a clutch pressure plate yourself, it is recommended that you seek the help of a professional mechanic or technician. This ensures proper installation and alignment, reducing the risk of premature wear or failure.

Break-in Period

After installing a new clutch pressure plate, it’s crucial to follow the manufacturer’s recommended break-in period. This typically involves driving gently for a specific number of miles to allow the components to bed in properly. Skipping the break-in period or driving aggressively during this time can lead to premature wear or failure.

Regular Maintenance

To keep your upgraded clutch pressure plate in peak condition, follow a regular maintenance schedule. This includes checking and adjusting the clutch pedal free play, inspecting the clutch components for signs of wear or damage, and replacing the clutch disc, pressure plate, and release bearing as needed.

Benefits of Upgrading Your Clutch Pressure Plate

Improved Vehicle Performance

An upgraded clutch pressure plate can significantly enhance your vehicle’s performance, particularly in high-torque or high-horsepower applications. By choosing the right type and material for your needs, you can achieve better clutch engagement, quicker engine response, and improved acceleration.

Increased Durability and Longevity

High-performance pressure plates often feature stronger materials and construction, which can increase the durability and longevity of your clutch system. This is particularly beneficial for vehicles subjected to extreme conditions, such as track use or heavy-duty applications.

Customized Driving Experience

Upgrading your clutch pressure plate allows you to tailor your vehicle’s performance to your specific needs and preferences. Whether you prioritize a lighter pedal feel, improved engine response, or increased torque capacity, an upgraded pressure plate can help you achieve your desired driving experience.

Conclusion

Investing in an upgraded clutch pressure plate can significantly improve your vehicle’s performance, handling, and driving experience. By understanding the different types of pressure plates, assessing your needs, and selecting the right material, you can unlock the full potential of your clutch system. With proper installation and regular maintenance, you’ll enjoy the benefits of an elevated ride and enhanced vehicle performance for years to come.